|

The item master setup of an purchased item determines how the item has a material requisition generated for it and how the system treats the item once it is received into inventory. Correct item setup is a critical factor in achieving your desired results while purchasing in OrderStream.

Buy to Order Items

Buy to Order Items are broken down into two categories:

1. Buy to Order Non Stock - Includes items where the stock flag is NOT checked in the item master

2. Buy to Order Stock - Includes items where the stock flag IS checked but no reorder quantities are specified in the item master

All buy to order items can be added to a material requisition using two methods:

| 1. | Manually selecting the item in the Material Requisition module |

| 2. | Generating a material requisition for specific sales orders or work orders via the Generate Material Requisition option within the Tools menu of the sales order or work order modules |

Both of these methods require some insight into how the system manages buy to order inventory.

1. Buy to Order Non Stock Inventory Management

OrderStream functions under the premise that all non stock buy to order items will be purchased each time demand is created for the item by the generation of a sales order or work order. This is the purpose of the Generate Material Requisition option in the Tools menu of the work order and sales order modules; selecting this option generates a material requisition for any buy to order items required by the transaction. OrderStream will NOT acknowledge existing inventory of a non stock buy to order item during the material requisition generation process (since the item is buy to order, system logic dictates that there should be NO existing quantity available), so a requisition is created for the entire quantity required.

When a purchase order is created for the non stock buy to order item from the Material Requisition module, the purchase order is linked to the work order or sales order the material requisition was generated for. How OrderStream handles the inventory at the time of purchase order receipt depends on whether the material requisition was generated from the sales order or work order module and if the item is required by a bill of material or the item itself is the item being sold (buy to sell). The table below presents the various scenarios which can be encountered and how OrderStream will handle the received inventory.

|

|

|

Material requisition generated from Work Order.

|

The received inventory is allocated to the work order line linked to the received item's receiving document line. This inventory is unavailable to be used for any other purpose.

|

Material requisition generated from Sales Order. Purchased item is required by the bill of material of the item being sold.

|

If a work order has been generated for the sales order by the time the item is received, the received inventory will be allocated to the work order line linked to the items receiving document line. This inventory is unavailable to be used for any other purpose.

If a work order has not been generated for the sales order by the time the item is received, the received inventory will be added into general unallocated inventory. When a work order is eventually generated for the sales order, OrderStream will attempt to allocate the inventory received for the sales order to the newly created work order; however, it is possible that another transaction could consume this inventory during the time between the receipt of the item and the generation of the work order. If this situation is encountered, OrderStream will attempt to allocate any existing available inventory which is present for the required item (using FIFO rules); if insufficient inventory is available, the inventory level of the item will be driven negative.

|

Material requisition generated from Sales Order. Purchased Item is the item being sold (buy to sell).

|

The received item is added to general unallocated inventory. When the sales order the item was received against is shipped, OrderStream will attempt to ship the exact inventory received against the sales order; however, it is possible another transaction could consume this inventory during the time between the receipt of the item and the time inventory is updated for the shipping document. If this scenario is encountered, OrderStream will consume any existing available inventory which is present for the required item using FIFO rules.

|

Note that a non stock buy to order item cannot be received against a completed work order line. If encountered with this scenario the user must either select a different work order line to receive the inventory against OR receive the item into unallocated inventory.

How Can I Check to see if I Have Existing Unallocated Inventory for a Buy to Order Item?

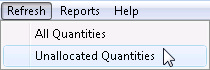

You can check to see if you have available (unallocated) inventory against a non stock buy to order item in the Material Requisition module by opening the Refresh menu and selecting Unallocated Quantities.

Mat Req Refresh Menu

Once you have done this, the Qty On Hand field on the Material Requisition form will be populated with the existing unallocated quantity on hand. Selecting All Quantities will populate the Qty On Hand field with the total inventory on hand for the item, both allocated and unallocated.

The reason why the Qty On Hand field is not populated automatically (without having to go to the Refresh menu), is due to the system logic that dictates that since the item is non stock buy to order, the item will be purchased for each transaction which requires it and there should be no existing unallocated quantity on hand.

Another method of checking to see if unallocated non stock buy to order items are present in inventory is to run a Data Integrity Check.

What if I Wish to Use Existing Unallocated Inventory for a Non Stock Buy to Order Item?

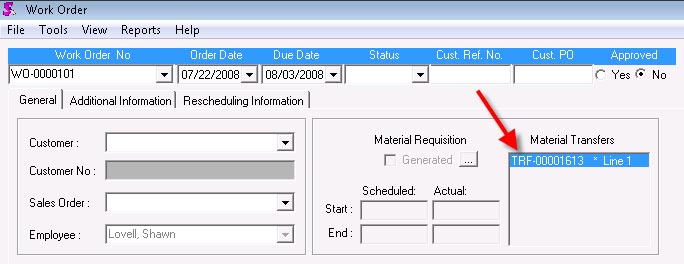

It is possible to use (consume) unallocated inventory that exists against a non stock buy to order item; to do so the existing inventory must be allocated to the work order requiring the item via an inventory transfer. An inventory transfer for a work order can be generated by selecting the Transfer Material option within the Work Order module's Tools menu. Once the inventory transfer has been generated, you can view it by double clicking the inventory transfer document number located within the Material Transfers box.

Double Click the Transfer Number to Open the Transfer

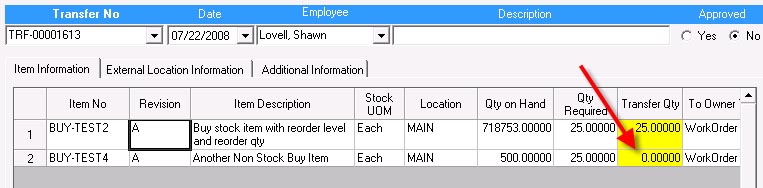

You will see that OrderStream automatically sets to the Transfer Qty to 0 for non stock buy to order items. This to prevent the amount of inventory allocated to the work order for these items from being doubled (since the inventory will be allocated to the work order when the buy to order item is received). If you wish to use existing unallocated inventory for the non stock buy to order item, type the amount to use into the Transfer Qty field.

Transfer Qty is set to 0 for Buy to Order Items

If you have elected to use existing inventory of a non stock buy to order item to satisfy the requirements of a work order, you no longer need to purchase it, unless not enough inventory was available to satisfy the work order's requirements in their entirety. If the work order's requirements have been completely satisfied, go to the Material Requisition module and use the work order filters to filter by the specific work order you have allocated the existing inventory to. Right click on the item you allocated and select Cancel Line/Mark As Generated to remove the item from the material requisition and prevent the item from being purchased unnecessarily. If the work order's requirements were only partially satisfied by the existing non stock buy to order inventory, go to the Material Requisition module and modify the quantity to buy by subtracting the quantity you allocated to the work order from the quantity required. When you are finished click the Save button. This will ensure that only the quantity you actually need to produce the work order will be purchased.

Work orders in OrderStream will NOT consume non stock buy to order inventory unless it has been allocated to the work order, either via receipt of the item (the typical system flow) or via an inventory transfer (atypical system flow).

2. Buy to Order Stock Inventory Management

When generating a material requisition for a work order or sales order which requires a stock buy to order item, the stock buy to order item will be included in the material requisition. The quantity to buy will be equal to the quantity which is required to satisfy the requirements of the source sales order or work order. Existing inventory for the stock buy to order item will not be taken into consideration by the material requisition generation process. You can check to see if you have available (unallocated) inventory against a stock buy to order item in the Material Requisition module by opening the Refresh menu and selecting Unallocated Quantities.

There are three differences in how OrderStream handles stock buy to order items vs. non stock buy to order items:

1. Stock buy to order items are not allocated to the work order requiring the item upon receipt of the item's purchase order.

2. When generating a work order inventory transfer, the Transfer Qty of stock buy to order items is equal to the Qty Required. This is required since the items are not allocated upon receipt.

3. Stock buy to order items can be consumed via work order completion without first being allocated to the work order.

|