|

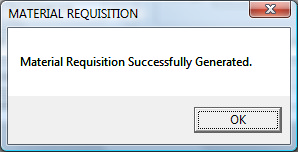

Material requisitions for buy to order items required by specific sales orders and work orders are generated by going to the Tools menu and selecting Generate Material Requisition. The time the material requisition generation process takes can vary based on the size of the bill of materials of the items selected on the sales order or work order transaction. When the material requisition has been successfully generated, you will be prompted with the following message.

Successful Mat Req generation prompt

All buy to order items (provided they have been correctly setup) will now be available for review in the Mat Req module; purchasing personnel can filter by Order By Date to ensure a purchase order is issued in enough time to ensure the item is received by the time it is required. See Material Requisition Dates and Colour Coding and Material Requisition Filtering for more information.

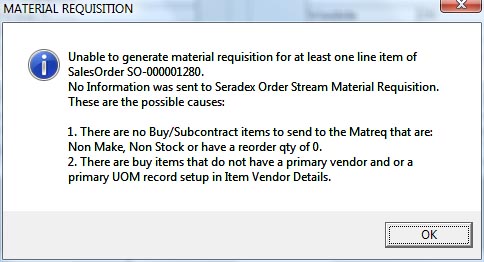

When generating a Material Requisition from the Sales Order or Work Order modules, if there are no buy/subcontract to order items on the transaction and/or an item has been improperly setup without a primary vendor, a message box will be displayed informing you that the material requisition was not generated and the possible reason(s) why.

Prompt displayed when material requistion is unable to be generated

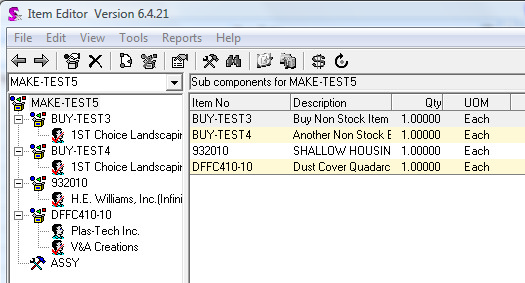

This is not necessarily a problem; it is possible that the material requisition was not created simply because one was not required due to the fact that no buy to order items are required to satisfy the transaction's requirements. If you believe that a material requisition should have been generated for the transaction, you can view the bill of materials for the item on each transaction line by clicking on the line you wish to view and pressing the F2 key (you can also right click on the line and select View Bill of Materials). This will open the Item Editor in spec mode where you can review the item and vendor setup to check for possible setup problems.

Item Editor module when lauched in Spec Mode

When checking the item setup to determine if an item has been setup as stock or buy to order, be sure to check the setting assigned to the item spec, not the item master. The material generation process references the settings assigned to the item spec. To check the item spec settings, in the Item Editor, right click on the item in question and select the View Item Spec option. This will open the Item Main form loaded with the item spec settings.

Material Requisition Generation when Multiple Work Orders are Assigned to One Sales Order Line

OrderStream's Work Order Generator module provides the ability to generate multiple work orders for a single sales order:

| 1. | Sales Order lines can be grouped onto separate work orders or each line can be placed on its own work order |

| 2. | Multiple work orders can be generated for a single sales order line (for example the sales order line quantity is 50 and you create two work orders with a quantity of 25) |

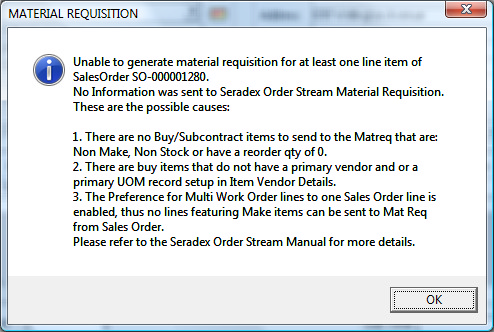

If your business processes dictate that you utilize the functionality stated in option #2, it is strongly recommended that your OrderStream Administrator enable the Mat Req Processing for multiple WO lines to one Sales Order line application preference. Enabling this application preference will prevent all material requisition generation from the Sales Order module for make items; you will be prompted with the following message when attempting to do so.

Modified prompt displayed when Mat Req Processing for multiple WO lines to one Sales Order line application preference is enabled

You must generate material requisitions for each work order separately from the work order module. This requirement is necessary because, in the event the source sales order line is modified, the material requirement alterations created as a result of the change cannot be distributed from the sales order line to the multiple work orders assigned to it.

Material requisitions can still be generated from Sales Order for buy items selected on any line of the sales order.

|