|

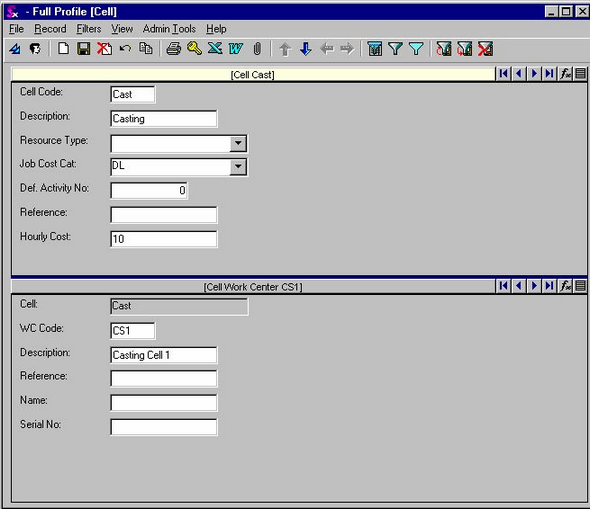

The Cell form is accessed by clicking on the [Lookups] bar, followed by the [Cell] icon within the OrderStream profile.

Cells and Work Centers are used for labor costing and scheduling. For scheduling purposes, scheduling treats all work centres within a cell as identical substitutes. During the scheduling process, an operation assigned to a cell will be scheduled on the first available work centre within that cell.

Important: Please consult with your installer on how to define cells and work centers. These definitions are a critical set-up consideration that will affect routings, scheduling, costing, factory calendar and plant capacity calculations. To change definitions after a large amount of data entry and history has occurred, can be costly.

Definitions:

| • | Work Center – A specific machine or individual that performs an operation on a routing. For example a Lathe or Shipping. The hourly cost for the Work Center comes from the Cell it is associated with. One Cell can have many Work Centers. |

| • | Cells – A Cell is a group of Work Centers that perform identical functions. In many cases a Cell will contain only one work center. If you have 5 identical lathes you would have a Cell with 5 Work Centers. If there is only 1 person in shipping you would have a Shipping Cell with 1 shipping Work Center. When adding a routing operation you select the Cell and enter a setup and run time. Scheduling assigns the specific work center within the Cell. If you need to schedule a piece of equipment it must be set up as a Cell. Any equipment or department that is a bottleneck resource or a pacing resource should be set up as a cell. |

Each Cell is assigned a hourly cost. If different pieces of equipment have different hourly costs they must be setup as different Cells.

| • | Tasks – Tasks are common activities that occur in a Cell. Assigning and setting up tasks is optional, they are used for reporting purposes only and do not have costs associated to them. A task is specific to a Cell if the same task can occur in two different Cells it must be entered twice. |

Example:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| • | Cleaning and sand blasting fittings |

|

|

|

|

One of the prime functions of Scheduling is to manage the capacity of each of your cells. Each cell is given an identification number, description, class, number of operators and hourly cost (if applicable).

The hourly cost of each cell can include wages, overhead, maintenance, consumable tooling or other variable costs associated with operating each work center. This cost will be applied to all operations occurring on the work center to calculate costing information. You should consult with your installer about the rational you will use for costing.

Tasks are common activities that can are performed at the work center. Commonly, tasks are used to sort daily buckets of work to save on set-up time. For example if paint red and paint black are two tasks, the daily work can be sorted so that all black items are painted together followed by all red items.

Field Reference

|

|

|

Job Cost Cat

|

Job Cost Category - Used to Group Costs in User Defined Categories for Custom Report Purposes ex Direct Material and Direct Labor

|

Resource Type

|

Labor, Material, Subcontract

|

Cell Code

|

Cell code Number

|

Description

|

Cell Description

|

Hourly Cost

|

Hourly Cost to Operate the Cell

|

Picture Path

|

Can Store a Bitmap File of the Cell - Used to Print on Custom Reports

|

Reference

|

User Controlled Text Field

|

Fixed Cost GL Account

|

General Ledger Account to Debit to Accrue Fixed Cost Allocations for Work Center Transactions

|

Variable Labour GL Account

|

General Ledger Account to Debit to Accrue Labor Cost Allocations for Work Center Transactions

|

Variable Machine GL Account

|

General Ledger Account to Debit to Accrue Variable Cost Allocations for Work Center Transactions

|

Annual Factory Charge

|

Annual Fixed Cost of the Factory to Pro Rate and Apply to this Cell

|

Annual Op Hrs

|

Forecasted Run Hours of this Cell

|

Annual Replacement

|

Annual Replacement Depreciation Expense to Apply to this Cell

|

Annual Setup Hrs

|

Annual Hours Spent Setting Up Cell

|

Factory Square Feet

|

The Total Factory Square Feet - Used to Allocated Fixed Costs to a Cell

|

Maintenance Cost

|

Forecasted Maintenance Cost of the Cell For the Year

|

Other Cost

|

|

Tooling Cost

|

Total Annual Tooling Cost Estimate Per Work Center

|

Total Fixed Cost

|

Total Annual Fixed Cost Per Cell

|

Variable Labour Cost

|

Variable Labor Cost

|

Variable Machine Cost

|

Variable Work Center Cost

|

Task Name

|

Tasks commonly performed at this Cell

|

Task No

|

Tasks commonly performed at this Cell

|

WC Code

|

Specific Work Center Within a Cell

|

Description

|

Work Center Description

|

Name

|

Work Center Name

|

Reference

|

User Controlled Text Field

|

Serial No

|

Serial Number of the Work Center

|

|