|

The Sub Contract module was developed to assist manufacturing companies dealing with sub contractors. The basic scenario is that a company sends material to a vendor to be processed in an operation like machining or painting. This business process involves material requisitions, purchase orders, inventory transfers, receipts and vendor invoicing.

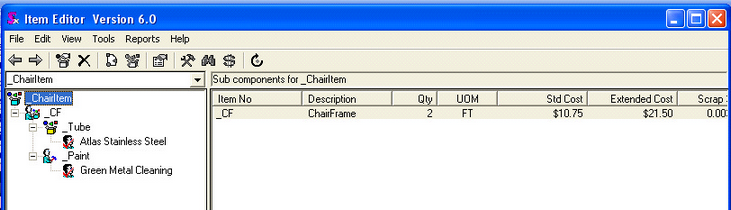

To illustrate the functionality we will use an example transaction from our sample database. The bill of material in the example illustrates the set up for an item; _ChairItem. The _ChairItem is manufactured by sending _Tube to a vendor (Green Metal Cleaning) for painting. The _Tube is purchased from Atlas Stainless Steel.

After the _Tube is painted, it is designated as a new item number _CF (Chair Frame). The Chair Frame can then be assembled with other components to make the _ChairItem.

Note: Vendor Locations for all Sub Contract Service Vendors MUST be identical tousing the Vendor’s AP Vendor Code.

|

|

|

|

|

|

|

|

|

|

_ChairItem

|

Chair

|

Make

|

Tracked

|

Normal

|

Yes

|

50

|

100

|

EACH

|

_CF

|

Chair Frame

|

N/A*

|

Tracked

|

Sub Contracted Parent

|

No

|

N/A

|

N/A

|

FT

|

_Tube

|

Tube

|

Buy

|

Tracked

|

Normal

|

Yes

|

500

|

100

|

FT

|

_Paint

|

Paint

|

Buy

|

No Tracking

|

Sub Contracted Service

|

No

|

N/A

|

N/A

|

EACH

|

The Sub Contract Parent designates the completed item after the sub contract is finished. The Sub Contract Service designates a sub contract operation.

|