|

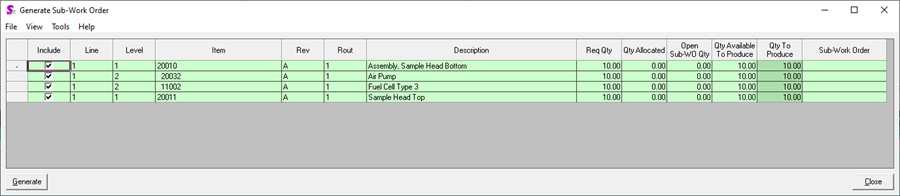

To create a sub work order from a primary work order, right mouse click and click on Generate Sub Work Order as seen in the following image.

With this form you can make work orders for the child components of a parent item.

Sub Work Order Inventory Transfers

OrderStream’s inventory transfer functionality will prevent duplicate item transfers when inventory is transferred for both a parent work order and for the related sub work order. Inventory transfers are automatically created at the time of sub work order generation when the possibility of data duplication is present. The parameters which determine the automatic creation of transfers are outlined in this section of the manual.

To take advantage of this functionality the following procedure must be followed in the same sequence:

| 1) | Generate the parent work order. |

| 2) | Create the inventory transfer. |

| 3) | Generate the sub work order. |

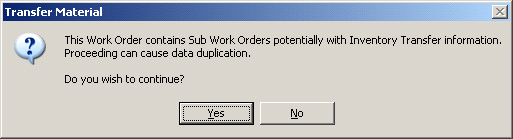

Failure to adhere to the above procedure creates the possibility that duplicate item transfers can be created if not properly managed. If the user attempts to create an inventory transfer AFTER generating a sub work order, the message below will be displayed to warn the user about the possible ramifications of continuing with the transfer:

Sub Work Order Auto Transfer Parameters

How the sub work order automatic transfer functions is determined by item setup, existing completed inventory transfers, existing open inventory transfers, and by application preference settings.

1) Make Stock Items with Transfer Make Stock Item flag Checked

| • | If the make item on the sub work order is stock AND the Transfer Make Stock Items flag in application preferences is checked, the make stock item will appear on the parent work order inventory transfer, but the child items of the make stock item will not be present. An inventory transfer will NOT be automatically created for any sub work orders generated. The sub work orders in this situation are treated similar to a stand alone work order in regards to the fact that when the sub work order is completed, the make stock item will be added to the item’s default inventory location and it WILL NOT be allocated to the parent work order. |

2) Make Non-Stock Items OR Make Stock Items with Transfer Make Stock Item flag NOT Checked

| • | If the make item on the sub work order is stock, but the Transfer Make Stock Items flag in application preferences is NOT checked, an inventory transfer is created for the total quantity required for the child items of the make stock item to be placed on a sub work order. The make stock item itself is not transferred. This functionality also applies to Make Non-Stock Items. |

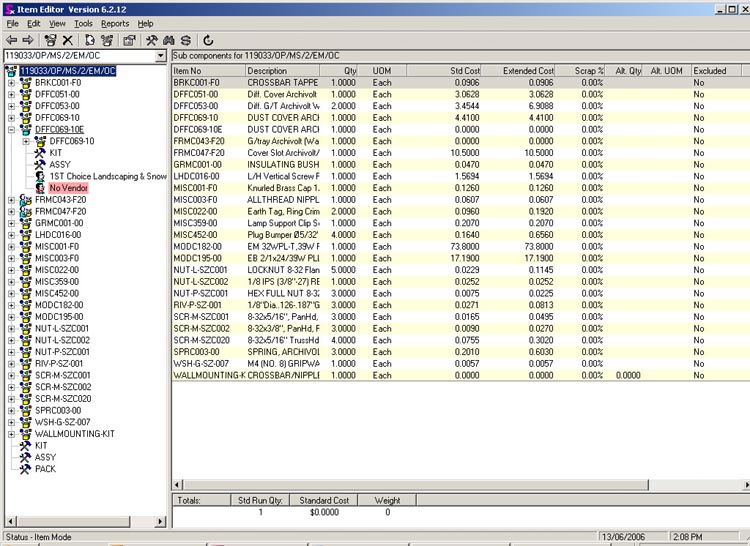

For example: 119033/OP/MS/2/EM/OC is the item on the parent work order. DFFC069-10E is a make stock item that is a child item to 119033/OP/MS/2/EM/OC. DFFC069-10 is a child item to DFFC069-10E. For the purpose of this example, the parent work order quantity is 50.

Parent WO Item

|

SubWork Order Parent Item

|

Quantity Req

|

Sub Work Order Child Item

|

Quantity Req

|

119033/OP/MS/2/EM/OC

|

DFFC069-10E

|

1

|

DFFC069-10

|

1

|

When an inventory transfer is created for the parent work order, DFFC069-10E is not transferred since the Transfer Make Stock Items flag is NOT checked. Instead, 50 DFFC069-10 are transferred against the parent work order. Now it is time to create the sub work order for 50 DFFC069-10E.

How inventory transfers are generated for the sub work order is further defined by whether the inventory transfer for the parent work order is open or completed.

| • | If the parent inventory transfer is open, an inventory transfer is automatically generated for the sub work order upon sub work order creation. During the creation of the transfer for the sub work order, the open transfer for the parent work order is updated to eliminate the duplication caused by the generation of the sub work order transfer. Using the example above, the 50 DFFC069-10 transferred against the parent work order are removed and a new transfer for 50 DFFC069-10 is created against the sub work order for DFFC069-10E. Note: if you looked at the parent work order transfer for this example, DFFC069-10 would still be present, but its quantity is set to 0. |

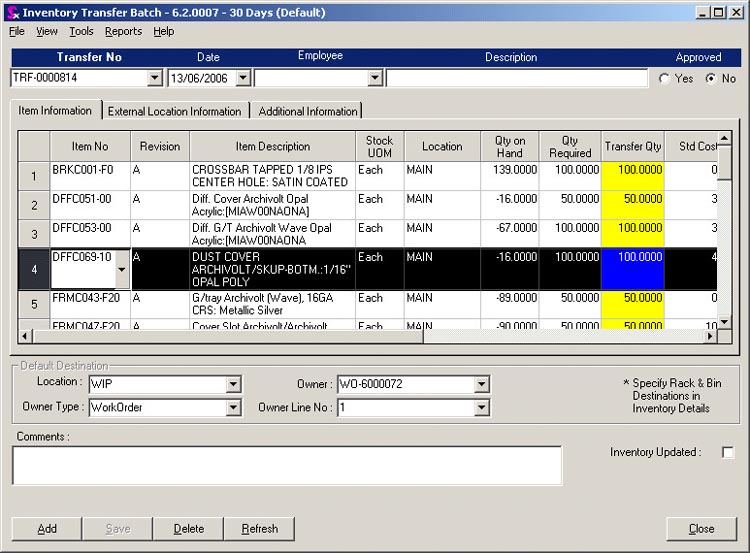

| • | If the parent work order inventory transfer is completed, the transfer cannot be updated in the method described above. Instead, when the inventory transfer for the sub work order is created, the transfer FROM location is set to WIP and the owner information is set to the parent work order and line. Thus, the inventory that was once allocated to the parent work order will be reallocated to the sub work order, preventing data duplication. |

Items with Multiple BOM Occurrences

It is possible to have more than one occurrence of the same item within a BOM. The item could appear in a parent item’s top level, or it could be nested within the BOM of a child make item. For example, DFFC069-10 resides on the top BOM level of 119033/OP/MS/2/EM/OC and it also reside in the BOM of DFFC069-10E.

How the inventory transfers are generated depends on the same factors previously indicated. If the item to be placed on a sub work order is make stock AND the Transfer Make Stock Items flag is checked, only the quantities of child items residing on the top level of the BOM will be transferred.

Make Parent Item

|

Buy Child (BOM Level 1)

|

Qty Req

|

Level 1 Make Item

(Sub Work Order)

|

Qty Req

|

Buy Child

(BOM Level 2)

|

Qty Req

|

119033/OP/MS/2/EM/OC

|

DFFC069-10

|

1

|

DFFC069-10E

|

1

|

DFFC069-10

|

1

|

Using our sample work order of 50 pieces of 119033/OP/MS/2/EM/OC in this scenario, 100 pieces of DFFC069-10 are required to satisfy both the parent and sub work orders. However since DFFC069-10 is a stock item and the Transfer Make Stock Items flag is checked, only the 50 pieces of DFFC069-10 required by the top BOM level will appear on the parent work order transfer. The 50 pieces required by the sub work order will appear on the automatically generated sub work order transfer.

Let’s modify our example and say that the Transfer Make Stock Items flag is NOT checked. As stated earlier the child material from the make item will appear on the parent work order inventory transfer, but since the same material appears elsewhere on the parent item’s BOM, the two values will be consolidated onto one inventory transfer line.

When the sub work order is created and the sub work order’s inventory transfer is automatically generated, the parent work order will be updated in the same manner as indicated previously. If the parent work order inventory transfer is open, the quantity required by the sub work order will be deducted from the parent work order transfer. If the parent work order transfer is completed, the quantity required by the sub work order is reallocated from the parent work order to the sub work order.

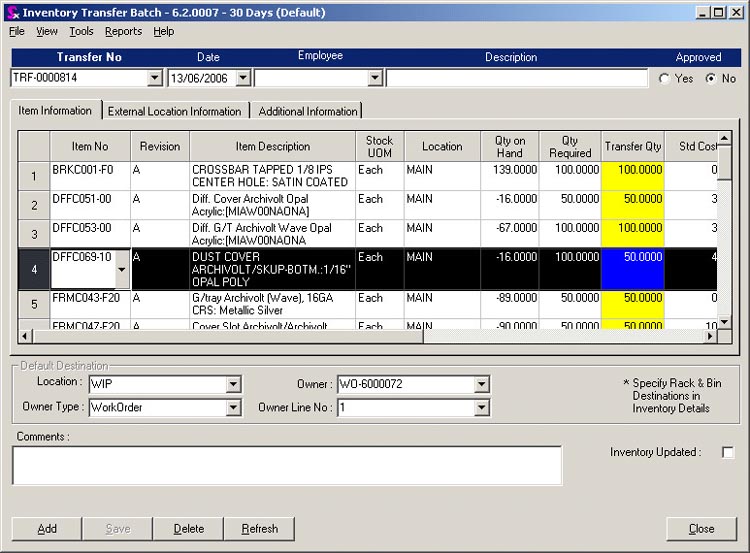

Consolidated Parent Transfer prior to Sub Work Order generation (item highlighted)

Parent Transfer after Sub Work Order generation (item highlighted)

Non Tracked Make Items

It is not possible to create sub work orders for non tracked make items. Such items will not be displayed in the sub work order generation form.

|