|

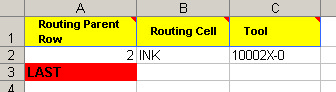

Tools created via the Tooling module can be assigned to a configured item's labour routing via the Tooling worksheet. A sample of a tool assigned to an operation is shown in the following image.

To link the tool to the correct instance of the desired work cell, enter the row number of the row in the Routing worksheet that the correct work cell resides on into the Routing Parent Row column. Enter the name of the correct work cell the tool is to be attached to into the Routing Cell column then enter the name of the tool into the Tool column.

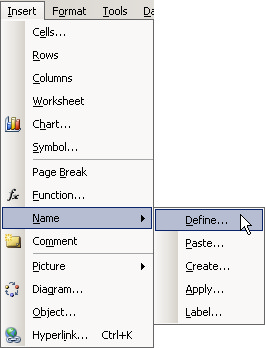

As in other product line worksheets, such as the BOM worksheet and the Routing worksheet, the last row to be read by the configurator must be defined. The last cell must be defined as ToolingLast. If this cell already exists in your product line worksheet, all you have to do is make sure this cell is after the last cell you have used to assign tools to operations. If the ToolingLast cell does not exist you can create it by doing the following. In Excel go to the Insert menu, expand Name and select the Define option.

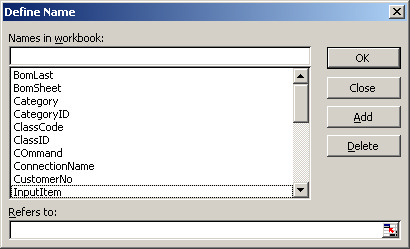

The following form will open.

Enter ToolingLast into the Name in workbook field then enter the cell you wish to apply the name to into the Refers to field. Click the Add button to add the name. It is recommended to identify this cell by typing LAST into the named cell or by setting a background colour for the cell.

|