|

Switching between states can be done by depressing the button on the menu bar that is shown within the red box in Figure A above, (It looks like a finger pointing to a list). When the button is depressed the Item Editor is in the Properties state. The key to getting the best results from the Inventory module begins with setting up the required information. The prerequisites for using the Inventory module include:

The Inventory module serves as the primary database for storing most product information. Both inventory items and non-inventory items (such as service and repair) are set-up in Inventory. A variety of fields are available for specific manufacturing related functions. Products may be organized into categories, classes and report groups for reporting purposes. Both the Inventory and Bills of Material modules offer a complete standard cost system in addition to an actual cost inventory.

Re-ordering Tools

The Material Requisition, Reorder Report and Inventory Inquiry are excellent tools for determining what to purchase or manufacture. Information is displayed as to what's on hand, on sales order, on back order, on purchase order, on work order, allocated, and in work-in-process. Reorder levels and reorder amounts may be established for each item.

Inventory Tracking

All inventory transactions (receipts, shipments, adjustments and transfers) are tracked and available for review. Month end reports provide all information needed for month end inventory accounting. The Physical Inventory Worksheet Report allows you to select items for counting, and the Adjustment screen provides a means for entering new balances and tracking the dollar effect of inventory adjustments.

Multiple Locations

The system provides for multiple warehouses or manufacturing plants and can maintain separate stock balances and costs by location.

Item Specs

Make Items

A common issue for manufacturing companies is to track revisions and changes to bills of material. Seradex has developed a system to manage the changes and allow overrides to bills of material on a transaction by transaction basis. Seradex uses Item Specs which are a snapshot in time of the bill of material as it existed when the transaction occurred. If changes are made new specs are created even though the Item Number has not changed. Users can elect to utilize Revision Control if desired.

When a Make item is created, labor and material components are added to create a bill of materials. This is the master bill of materials. Unlimited changes can be made to the master bill of material.

The first time the Make item is used on a transaction including estimate, sales order, work order or invoice, an exact copy of the master bill of material is made. This copy is called an Item Spec. This same spec will be referenced on all future transactions until one of the following events occur:

| 1) | A user modifies the bill of material at the transaction level. For example, at estimating a user adds or removes a labor or material component. This will trigger the creation of a new spec that is unique to that transaction. If the Estimate is converted to a Sales Order and Work Order each subsequent transaction will refer to the new spec. This spec is never deleted. If your customer calls in at a future date requesting spare parts, the specific spec can be located and reviewed as the “As Ordered Bill of Material”. |

| 2) | If the master bill of material is changed then a spec will be generated the next time a new transaction is initiated. A change can include any additions or deletion of material or labor or changing item master information such as location, reorder quantity, tracking type, category, etc. Several changes at various points in time can be made but a new spec will not be generated until a transaction forces the creation. |

Buy Items

Buy items are treated in a similar manner as make items. When a Buy item is first created the item master and item vendor information is entered. At this point a spec for the item is not created. A spec will be created when:

The Item is placed on a Material Requisition or Purchase Order. The receipt and inventory records will record the spec. If any item master information is subsequently changed the next Requisition or Purchase Order for this item will trigger the creation of a new spec.

If a Buy item is placed on a bill of material and that bill of material is used on a transaction, a new spec for the Buy item will be created.

Configured Items

When a configured item is first created on an estimate, sales order or work order, a spec is also created listing the unique bill of material. If the user changes any options or choices and saves, a new spec will be created.

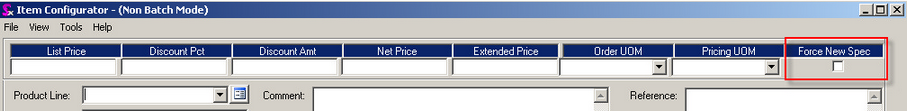

If the user clicks the Force New check box and clicks the save button on the bottom of the form, a new spec will be created.

This is typically used when testing the configurator product line excel workbooks. By default a new spec will not be created if the same options are chosen as a previous configured product. This saves database space as a new spec is not created every time a common configured product is chosen.

In Application Preferences there is a flag to Always Force New Spec. If this is set on, a new spec will be created even though the current transaction includes an identical configuration to a previous order. This is the safest option if many changes are being made to the excel sheets. If there was an error in the Excel workbook that is corrected and Always Force New Spec is not switched on, subsequent transactions would refer to the old and incorrect spec.

Item Revisions

The system enables the user to copy an item and create the same item number with a new revision. Bill of Material changes can now be applied to the new revision. This becomes the master bill of material for that revision and a new spec will be created if the new item/rev is picked for a transaction. The user will also be able to select the first item and revision (unless it was tagged inactive).

|