|

Cycle counting is an important tool in achieving inventory accuracy. It acts as a count rotation through your inventory parts.

In order to get the most of your cycle count you must make sure you items have the proper class information (A, B, C designation). The OrderStream A,B,C Analysis Report – Buy Items standard report provides valuable item information to aid you in your decision, such as the total amount of the item received during the current year, the value of the item purchased on annual basis and the total value of the item purchased. The report will display the current class assigned to the item and a class which is recommended by the system to be assigned to the item. The recommended class is just that – a recommendation; the ultimate decision is up to you.

Research shows that the more often a product is received or shipped, the less accurate its computer stock balance is. This makes sense. Every time someone goes to the bin there is an opportunity for a mistake to occur. For example, material can be put away in the wrong bin or the wrong product can be taken to fill an order.

The Ranking Method directs you to count the items with a large number of dollars flowing through inventory. The ranking is based on "Pareto’s Law" (named for the late Italian economist Vilfredo Pareto). His law states that, in general, 80% of the results of any process is produced by 20% of the contributing factors. Applied to inventory, this means that approximately 20% of your inventory items are responsible for 80% of your stock sales.

•

|

"A" class items (responsible for the top 80% of sales) count six times per year

|

•

|

"B" class items (responsible for the next 15% of sales) count three times per year

|

•

|

"C" class items (responsible for the next 5% of sales) count twice per year

|

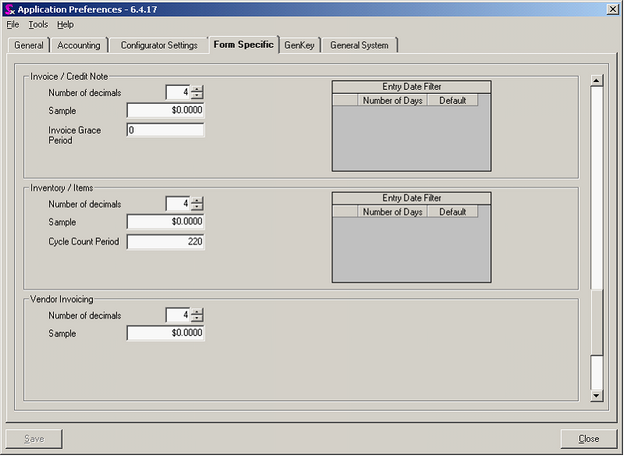

Before beginning a cycle count, you should verify the number or working days currently established for the cycle count calculations. This can be found on the Form Specific tab of Application Preferences.

The cycle count period of 220 represents the typical number of working days in a year. If your company has more or less working days within a year, please adjust that value as needed.

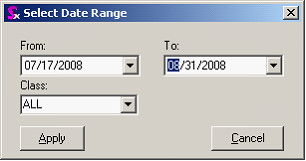

To initiate a cycle count, under Tools select Run Cycle Count. Now use the form below to select the appropriate date range and class (if relevant).

This date range, in combination with the cycle count period and item classifications determines how many and which items to count. A sample calculation would be as follows:

|

|

43

|

A Class

|

3

|

B Class

|

400

|

C Class

|

446

|

Number of Tracked, Active Items in Database

|

|

|

|

|

|

|

Cycle Count Period

|

07/17/2008

|

08/31/2008

|

44

|

# of A's to count

|

(43*44*4)/220

(# of Active, Tracked Items in Class * # of CycleDays * 4) / Cycle Period

|

34

|

# of B's to count

|

(3*44*2)/220

(# of Active, Tracked Items in Class * # of CycleDays * 2) / Cycle Period

|

1

|

# of C's to count

|

(400*44)/220

(# of Active, Tracked Items in Class * # of CycleDays) / Cycle Period

|

80

|

Total Items to count

|

115

|

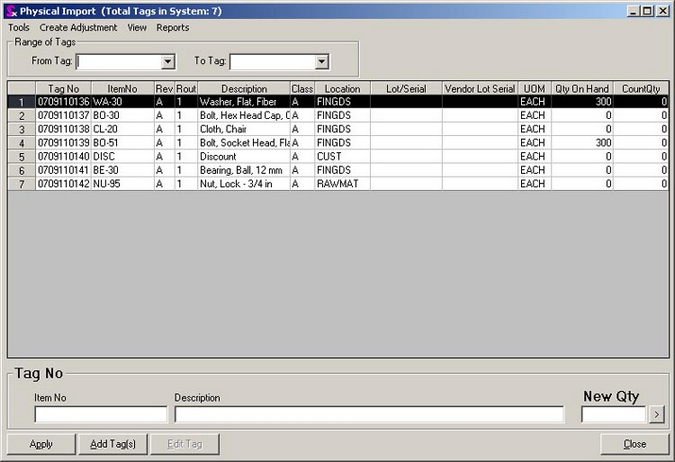

Now a specific set of items will display on the form as shown below.

Using this sample database, you will notice that the first 7 "A" class items are displayed .

Counting the tags works and creating the subsequent inventory adjustment works in the same fashion as conducting a full physical inventory count. See Entering the Counted Quantities and Creating the Physical Adjustment for more information.

Next time you run the cycle count the next group of items will appear. The number of items counted will depend upon how many parts you have for that particular class.

Notes:

| • | The system evaluates the Items in each class to determine which should be added to the list of items to count. More recently counted Items are last to be added to the list. Items that have not been counted will be added first. For Items that were counted at the same time, they are added in the order that they were entered into the system. |

| • | If an item on the cycle count list is not counted, it will not show on the next physical count run. |

|